Tattoo Machines - Choosing The Right One For Your Needs

There are various types of tattoo equipments. These equipments can be made use of to make different layouts. However, many professionals choose to utilize only one sort of maker. This is due to the fact that the top quality of the machine will certainly be compromised if the user changes the layout. In this article, we will certainly check out the benefits and drawbacks of each type of tattoo device. Ideally, these ideas will certainly assist you choose the best device for your needs. You can learn more concerning tattoo devices by continuing reading!

The first thing to keep in mind when picking a tattoo device is the brand. The brand should be understood for its high quality. The tattoo equipment should be durable, and also its parts need to be made from resilient materials. We advise that you select a high-performance brand name. This way, you can be certain that the tattoo machine will certainly last a long period of time. There are various brand names of premium devices, which are easy to use. The most effective option depends on your demands.

You might likewise want to pick a brand name that uses favorable reviews. In this manner, you can be certain that the brand deserves purchasing. It can be difficult to know which one to purchase. There are various kinds of tattoo equipments, as well as it can be tough to select the appropriate one. Some makers feature totally free devices, however others feature a membership fee. You will have to pay for these if you intend on buying the equipment.

If you are not sure whether you should pick a costs or affordable brand, you need to take into consideration the sort of device you need. By doing read this post here , you will be able to find the one that is right for your requirements. If you do not wish to spend money on a tattoo maker, you ought to take into consideration an affordable one with adjustable components. The most effective makers will certainly likewise feature a service warranty as well as an excellent customer care. You need to consider a guarantee.

It is very crucial to pick the appropriate type of tattoo machine for your needs. If you are searching for one of the most affordable price, it is necessary to examine the testimonials and rankings of each tattoo machine you get. If you have any type of doubts, you can constantly contact the producer. These evaluations will help you decide which one is best for you. If you are not sure, it will certainly be easier to choose a low-quality machine. A good choice is to look for a budget-friendly one. The high quality of a tattoo maker is extremely dependent on its brand name.

If you are looking for a high quality tattoo equipment, it is essential to pick one that has a warranty as well as works in your place. https://postheaven.net/eusebio0284edwardo/you-may-not-know-which-brand-name-is-best-for-you-but-it-is-very-important is likewise essential to select a machine that is inexpensive and also practical for you to utilize. Some designs are much cheaper than others, so they need to be bought if you are looking for a durable as well as inexpensive maker. There are several brand names of tattoo devices, however the ones that you choose need to be one that is suitable for your demands.

A top quality tattoo machine is essential to prevent problems. A tattoo device is not just a costly tool. It needs to also be easy to use as well as preserve. You must likewise take into consideration the supplier's credibility. Ensure that you purchase a reliable maker. If you don't know the maker, you'll have to request references. The company must be a brand that has a great online reputation in the market. It is very important to select a reliable firm that provides a service warranty for their products.

A good tattoo machine should be inexpensive. coleman widow style combo frame liner tattoo equipment will certainly cost you less. It must likewise have the functions as well as benefits of the brand name you desire. Besides, it must be able to publish in different shades. Those devices will need to be suitable with the brand name you pick. If you aren't sure, seek a brand that has a great warranty. It will certainly be simple to obtain a warranty from the producer as well as will last for a very long time.

Choosing a tattoo maker that has a service warranty is important. It must give a guarantee. A maker can offer warranties for their devices. While numerous manufacturers may supply a 1 year guarantee, you must also inspect the guarantee of the tattoo equipment. It must also have a great reputation in the tattoo neighborhood. They ought to have a solid track record. If you pick to purchase a brand-new equipment, make sure that it is made from high-grade elements.

Tattoo Machines - Selecting The Right One For Your Demands

There are various kinds of tattoo devices. These devices can be made use of to alter designs. Nevertheless, the majority of experts pick to use just one type of device. This is due to the fact that the high quality of the machine will be compromised if the customer changes the style. In this write-up, we will consider the advantages and disadvantages of each type of tattoo machine. Ideally, these tips will certainly aid you choose the best equipment for your requirements. You can learn more concerning tattoo machines by keeping reading!

The first thing to remember when choosing a tattoo equipment is the brand name. The brand name needs to be understood for its high quality. The tattoo maker must be durable, and its components must be made from resilient products. We suggest that you select a high-performance brand. This way, you can be certain that the tattoo equipment will certainly last a very long time. There are different brands of premium makers, which are easy to use. The most effective selection depends upon your requirements.

You may additionally want to pick a brand name that supplies favorable evaluations. In great site , you can be certain that the brand name is worth buying. It can be difficult to understand which one to purchase. There are various kinds of tattoo devices, and it can be hard to choose the appropriate one. Some makers feature totally free accessories, yet others include a registration charge. You will certainly need to pay for these if you plan on acquiring the device.

If you are not sure whether you ought to pick a costs or economical brand, you should consider the type of machine you require. In this manner, you will be able to discover the one that is right for your requirements. If you do not wish to spend money on a tattoo maker, you ought to take into consideration a cheap one with flexible parts. The best equipments will likewise feature a guarantee and also an excellent customer care. You ought to think about a service warranty.

It is very vital to pick the best type of tattoo equipment for your needs. If you are seeking one of the most inexpensive price, it is necessary to check the evaluations and scores of each tattoo machine you purchase. If you have any questions, you can constantly get in touch with the supplier. These reviews will certainly aid you determine which one is best for you. If you are unsure, it will certainly be easier to pick a low-quality machine. A great choice is to try to find an economical one. The top quality of a tattoo equipment is extremely based on its brand.

If tattoo machines near me are looking for a top quality tattoo device, it is essential to select one that has a warranty as well as operates in your area. It is additionally vital to pick a machine that is inexpensive and hassle-free for you to make use of. Some versions are much cheaper than others, so they should be bought if you are seeking a durable as well as inexpensive machine. There are several brands of tattoo machines, yet the ones that you select should be one that appropriates for your needs.

A top notch tattoo equipment is needed to avoid complications. A tattoo machine is not merely a pricey tool. It needs to additionally be easy to use and maintain. You ought to additionally think about the maker's credibility. Ensure that you get a trustworthy equipment. If you don't know the manufacturer, you'll have to ask for recommendations. The company needs to be a brand that has a great reputation in the market. It is very important to choose a trustworthy company that supplies a service warranty for their products.

A great tattoo device should be inexpensive. A top notch tattoo maker will certainly cost you much less. It needs to additionally have the attributes and advantages of the brand you want. Besides, it must have the ability to publish in various shades. Those machines will certainly require to be suitable with the brand name you choose. If you aren't certain, try to find a brand that has a good service warranty. It will be simple to get a warranty from the manufacturer as well as will last for a very long time.

Choosing a tattoo device that has a service warranty is essential. It needs to supply a warranty. A producer can use guarantees for their equipments. While many suppliers might use an one-year warranty, you must also check the warranty of the tattoo device. It should additionally have a great track record in the tattoo area. They need to have a solid credibility. If you select to buy a brand-new device, ensure that it is made from top quality parts.

Tattoo Equipment Manufacturers - Picking Tekori Tattoo Kits

Tattoo experts don't typically state which tattoo maker brand name is the very best, but they will tell you that it's an excellent idea to go with a top quality maker that has a strong product lineup. A well-decorated listing or fluffiest description will not make anything shine, yet a brand name that has a big profile of different products will stick out. Relying on what kind of work you're mosting likely to be doing, this can be a terrific over view to discovering the most effective maker for your demands.

Some makers utilize toughened up device steel for mechanical parts, which won't flex or break gradually. These components are likewise protected with aircraft composite to endure shock. And also as a result of their toughness, the tattoo machines are sterilizable. These equipments come with a 2 year warranty on the coils. A great device is durable and also very easy to maintain, however still calls for the customer to make minor changes to match the sort of job they'll be doing.

The most effective device to utilize for your needs is one that functions well for several applications. This version has adjustable needles, 5 colors and is quiet. It has a Hex Drive motor system that lowers axial load on the motor shaft. A tattoo equipment can also be tuned by hand, making it easy to regulate the rate and also accuracy of the stroke. When it involves quality, you will not need to spend a lot of time and effort adjusting the settings.

A rotary machine can do every little thing from lining to shielding. https://www.elle.com/beauty/makeup-skin-care/a28806110/lip-blushing/ is for shielding and also sculpting lines. It is designed to function well with bigger needle collections, while the brief stroke is for cellular lining. If you're simply beginning, it's recommended that you obtain a device with both short and also long stroke capability. They're both dependable and also comfy to utilize, and you'll like them! Just see to it you purchase from a trusted supplier.

There are various other elements to take into consideration prior to making your decision on a tattoo maker. The layout of the device is a vital element. If you're seeking an all-purpose tattoo machine, you'll require to take into consideration the size of the needles. An equipment with a big team of needles is finest matched for all-purpose cellular lining and also shading. It should also have an auto cooling attribute. When it involves the design, the solong model is a costs selection, and it's also simple to operate.

The Sunskin Stillo is a dedicated-task equipment. It has an OEM patented titanium device and is plated in seven colors. Unlike a rotary tattoo machine, its style is lightweight and will not trigger hand fatigue. Its reduced weight makes it easy to navigate, which is a major plus for a tattoo equipment for novices. The Solong is the perfect selection for the average tattoo artist. The price of a used rotating tattoo machine is high, but it's worth it if you're serious about getting a top notch product.

InkJecta is a tattoo equipment maker that declares to be the largest rotating tattoo machine producer in China. This brand name has been around for greater than a decade as well as is the only one that manufactures this sort of tattoo maker. The company isn't terrified to market its item and also isn't worried to flaunt that its tools is the best. It also provides a service warranty and also is recognized for its top quality workmanship.

One more tattoo maker supplier that is based in Southern California is Dead Nuts Ink. This brand name is widely known for their coil tattoo makers. Their coils are constructed from high-grade, billet airplane aluminium. Its framework is powder-coated for a durable coating. The business also makes its very own electric motors, which are the essential parts of a maker. Moreover, this maker is well-known for making high-grade metal frameworks.

A well-crafted tattoo machine has a smooth look and also is easy to use. The company's coil tattoo equipment is made from stainless steel as well as can laying ink in a solitary pass. These coil makers are compatible with standard cartridges as well as needles. Inks are deposited with the same rate. The difference in these kinds of equipments is that the rotary machines are lighter as well as simpler to make use of than the lining ones.

Tattoo Machines - Picking The Right One For Your Requirements

There are different sorts of tattoo machines. These devices can be used to alter styles. However, most experts choose to utilize only one sort of maker. This is since the quality of the machine will be endangered if the customer changes the design. In this write-up, we will certainly look at the pros and cons of each kind of tattoo machine. Hopefully, these pointers will assist you choose the right device for your requirements. You can find out more about tattoo equipments by continuing reading!

The first thing to bear in mind when picking a tattoo device is the brand name. The brand name should be understood for its quality. The tattoo equipment need to be durable, as well as its components must be made from sturdy products. We recommend that you choose a high-performance brand name. By doing this, you can be certain that the tattoo equipment will last a very long time. There are various brands of premium devices, which are easy to use. The best choice depends on your needs.

You may additionally want to select a brand that offers positive reviews. This way, you can be sure that the brand deserves purchasing. https://docs.google.com/spreadsheets/d/1rvU1o2i5P6bQRYKOpS_WqUGynoGzNwzdAT2PE1RbcF4/edit?usp=sharing can be difficult to recognize which one to get. There are many different sorts of tattoo devices, and it can be tough to select the appropriate one. Some makers feature complimentary accessories, but others include a subscription fee. You will certainly need to spend for these if you plan on acquiring the maker.

If you are unsure whether you need to select a costs or affordable brand, you should take into consideration the type of maker you require. By doing this, you will certainly be able to locate the one that is right for your needs. If you do not intend to invest cash on a tattoo equipment, you ought to consider an affordable one with adjustable components. The best equipments will certainly additionally come with a warranty and also an excellent customer support. You need to take into consideration a warranty.

It is extremely important to pick the ideal sort of tattoo equipment for your demands. If you are seeking one of the most inexpensive price, it's important to examine the reviews and scores of each tattoo device you get. If you have any kind of questions, you can always contact the manufacturer. These testimonials will assist you determine which one is ideal for you. If you are unclear, it will certainly be less complicated to pick a low-grade machine. An excellent option is to seek a cost effective one. The high quality of a tattoo machine is highly based on its brand.

If you are searching for a top quality tattoo device, it is important to pick one that has a service warranty and also works in your place. It is likewise essential to select an equipment that is inexpensive and practical for you to make use of. Some designs are more affordable than others, so they should be bought if you are looking for a resilient and also low-priced equipment. There are many brand names of tattoo devices, however the ones that you select must be one that is suitable for your needs.

A top quality tattoo equipment is needed to prevent issues. A tattoo equipment is not merely an expensive tool. It must additionally be easy to use and preserve. You must also think about the manufacturer's online reputation. Make sure that you acquire a trustworthy machine. If you do not understand the manufacturer, you'll need to request references. The business must be a brand that has an excellent track record in the industry. It is important to choose a respectable firm that offers a warranty for their products.

A good tattoo machine need to be inexpensive. A premium tattoo equipment will cost you less. It needs to likewise have the attributes and advantages of the brand name you want. Besides, it should have the ability to print in various colors. Those equipments will require to be suitable with the brand name you select. If you aren't certain, look for a brand that has a good guarantee. It will certainly be very easy to obtain a guarantee from the producer as well as will last for a long time.

Picking a tattoo device that has a guarantee is essential. check out this site needs to offer an assurance. A maker can use warranties for their equipments. While several producers might offer an one-year service warranty, you need to additionally inspect the guarantee of the tattoo machine. It needs to additionally have an excellent track record in the tattoo neighborhood. They need to have a strong reputation. If you select to get a new machine, make sure that it is made from high-quality components.

Tattoo Machines - Picking The Right One For Your Demands

There are different types of tattoo devices. These equipments can be used to alter styles. Nonetheless, most professionals choose to use just one sort of device. This is because the high quality of the equipment will be endangered if the user transforms the design. In this article, we will certainly check out the pros and cons of each sort of tattoo equipment. With any luck, these tips will certainly aid you pick the ideal machine for your demands. You can discover more about tattoo machines by keeping reading!

The first thing to keep in mind when choosing a tattoo machine is the brand name. The brand name must be recognized for its high quality. The tattoo equipment need to be durable, and also its elements need to be made from resilient products. We suggest that you select a high-performance brand name. This way, you can be sure that the tattoo equipment will certainly last a very long time. There are numerous brand names of premium makers, which are easy to use. The very best choice depends on your requirements.

You may additionally intend to pick a brand name that supplies favorable testimonials. This way, you can be certain that the brand name deserves buying. It can be tough to know which one to acquire. There are many different sorts of tattoo devices, and also it can be tough to choose the appropriate one. just click the up coming internet site include free devices, but others come with a registration cost. You will have to spend for these if you plan on buying the device.

If you are not exactly sure whether you need to choose a premium or affordable brand, you must consider the type of maker you require. This way, you will certainly be able to discover the one that is right for your demands. If you do not wish to spend money on a tattoo device, you must consider an affordable one with adjustable parts. The best devices will additionally feature a warranty as well as a good customer service. You must think about a warranty.

It is really essential to pick the appropriate sort of tattoo maker for your requirements. If you are searching for the most budget-friendly price, it is very important to inspect the testimonials as well as scores of each tattoo device you purchase. If you have any kind of uncertainties, you can constantly call the maker. These evaluations will certainly assist you make a decision which one is best for you. If you are uncertain, it will certainly be easier to choose a low-grade machine. A good alternative is to look for a budget-friendly one. The top quality of a tattoo machine is extremely based on its brand name.

If you are trying to find a quality tattoo machine, it is vital to select one that has a warranty as well as operates in your area. It is likewise essential to pick a device that is affordable and convenient for you to make use of. Some versions are more affordable than others, so they ought to be purchased if you are searching for a long lasting and low-priced equipment. There are several brands of tattoo makers, however the ones that you select must be one that is suitable for your needs.

A premium tattoo machine is needed to avoid issues. A tattoo maker is not simply a costly device. It should additionally be easy to use as well as keep. You need to also consider the supplier's track record. Make sure that you buy a credible device. If you do not understand the supplier, you'll need to request for recommendations. https://www.mmsonline.com/articles/milling-machine-control-system-leaves-a-mark-on-tattoo-machine-developer ought to be a brand name that has a good credibility in the sector. It is very important to pick a reputable firm that offers a service warranty for their products.

An excellent tattoo maker should be affordable. A top quality tattoo device will cost you less. It ought to likewise have the features as well as advantages of the brand you want. Besides, it needs to have the ability to print in various shades. Those makers will require to be suitable with the brand name you choose. If you aren't sure, try to find a brand name that has a good service warranty. It will certainly be simple to get a guarantee from the maker and will last for a very long time.

Selecting a tattoo maker that has a service warranty is essential. It must provide an assurance. A producer can use guarantees for their makers. While several producers may provide an one-year guarantee, you need to additionally check the guarantee of the tattoo device. It ought to additionally have an excellent credibility in the tattoo area. They need to have a solid online reputation. If you pick to acquire a brand-new equipment, see to it that it is made from high-quality parts.

An Overview To Tunnel Pasteurization For Food Market

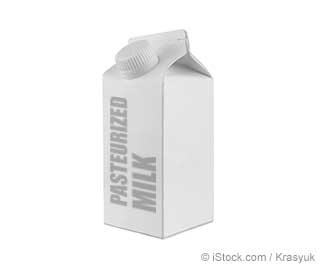

The term "Tunnel pasteurized food" refers to the process of thermal pasteurizing premium fluids made use of in the food market. Pasteurization is a total treatment designed to lessen any unfavorable results on the high quality, structure or preference of the final product. Top quality pasteurizers are designed for several applications consisting of making fresh juice, food preparation with oils, dealing with juices and also various other alcoholic beverages, dealing with milk items and also preparing sauces as well as marinades.

Tunnel pasteurizers can be categorized into two types: batch pasteurizers and also constant flow pasteurizers. In the batch pasteurizer, a continuous flow system draws out the heated fluids in one container and afterwards sends out the heated fluid via a constant course to one more container. Set pasteurizers are normally set up in continuous-flow systems since it is simpler to preserve. The constant flow system uses gravity to blend the components before the conversion to sterilized kind. A batch pasteurizer additionally permits an extra constant warmth transfer to the completed product during the production procedure.

Pasteurizing fluids with continuous circulation systems use the principles of dissipation and suction. The heated fluids are required through a vacuum tube or evaporator. The heated fluids are after that transferred on the drier plate by the evaporation procedure. These kinds of pasteurizers utilize a temperature level to manage the price of cooling of the item.

Tunnel pasteurizers that make use of warmth compression techniques utilize heated pipes that apply consistent stress to the warmed fluids. A tiny gap is developed between the pipeline as well as the surface to be cooled. As the temperature of the fluid go through the pipeline, the temperature degrees are consistently kept an eye on and changed. This process is described as superheating. When superheated liquids pass through the pipeline, they swiftly cool down to ambient temperatures.

Several pasteurizers for drink manufacturing utilize high-pressure warm water flows for the activation of microbes. Other types of pasteurizers utilize a drywall jointed barrier. The application of such obstacles assist stop the growth of mold, mildew and various other fungi. When such microorganisms are introduced right into the production process, it can have an unfavorable effect on the high quality of the completed item. Such disadvantages can be lessened by Tunnel pasteurization approaches.

One more usual use Tunnel pasteurizers remains in the manufacturing of medical products. Specific pharmaceutical products call for the consumption of a number of bacteria before their complete break down within the body. In some cases, this might be hard to achieve because of space constraints and other variables. Others might need to make sure the proper temperature levels throughout a production line. Tunneling can assist meet these demands by supplying a constant and regulated temperature setting.

Tunneling Sterilizing systems are offered for purchase and also can additionally be used in the house. There are a number of home recipes which have actually been developed to generate high focus of these bacteria. https://www.marketwatch.com/press-release/non-thermal-pasteurization-market-size-to-record-198-cagr-during-2020-2027- can be mixed along with conveniently offered ingredients to create an efficient mix for using in the production of a range of foods and also beverages. All resources must be entirely dry prior to make use of in these dishes.

Tunnel pasteurizers make terrific alternatives to typical ways of pasteurizing beer because of their efficiency in rapidly bringing any item to completely ripe, all set to consume temperature level degrees. These items are offered offer for sale online and in a variety of various styles. Numerous retailers that provide these products also use professional customer care to respond to any kind of concerns or inquiries one may have concerning their products. These extremely efficient systems are widely prominent due to their straightforward, fast, and also economical production methods. It is easy to understand why companies throughout the globe usage Tunnel pasteurizers in the production of their most popular drinks and also various other goods.

The Tunnel Pasteurization Refine And Also Its Advantages

The Tunnel pasteurization procedure is one way to ensure quality red wines are created for consumers. When utilizing this procedure, the pasteurization of white wine or grape juice occurs in a storage tank which contains both the white wine and the product being maintained at the same time. There are three temperature level degrees that can be made use of in this kind of pasteurization strategy. The initial 2 approaches are the sublimation and the carbon dioxide settings.

Tunnel pasteurization procedure used in the production of beer is often described as the coolship fermentation. This process makes use of regarding two quarts of beer for every single gallon of item produced. Throughout this procedure, the coolship vessel having the beer is positioned in a cool dark place such as a basement or garage. The temperature level is typically between forty-five and fifty-five degrees Celsius.

A lot of the items created in the United States undergo the Tunnel pasteurization procedure. In order to produce the premium white wines, pasteurizing the item has to occur at the correct temperature level and for an adequate size of time. The product that should go through this procedure is referred to as quenched beverage items. The items that are used to make sodas, teas, and also flavored drinks are called quenched beverages. Both major kinds of products that need to undergo this procedure are red wine and also sparkling wines.

“USING THE SENSES FOR BREWERY OBSERVATIONS AND PROCESS CONTROL”

— PRO ENGINEERING (@Daveone1) October 26, 2021

Article Release for Brewmasters & Beverage Makers by David Kapral, Founder/CEO: Brewing Consulting Services, LLC

Click for full article: https://t.co/SLNedCmYOh

PRO Engineering / Manufacturing Inc.

414-362-1500 pic.twitter.com/weQW3Jt26S

There are three methods to pasteurize drinks. These include the warm water/cool water, the cold water/cool water set pasteurization procedure, and also the spray container pasteurization procedure. There are distinctions in between these methods. It is very important to keep in mind that the longer the bottles are entrusted to undertake the Tunnel pasteurization process, the much better the high quality of the product will be.

relevant internet page means to use this technique is for the packaged bacteria to get in the bottles. When the bottles are secured, they do not present any type of threats of the bacteria expanding as well as increasing when inside. This is because the microorganisms grow at a quick rate when they come in contact with some sort of food source like the microbes that expand inside the packaging line. Once the bacteria are killed or dried out, the bottles are then placed on a shelf for later usage. Throughout the production procedure, the business can additionally pasteurize the beer prior to it comes into contact with the packaging line.

The service life of the packaged items that are sterilized making use of the Tunnel pasteurization process can additionally last for as long as 1 day after the items are sealed in the packaging lines. With the shelf life of the packaged beverages and also other carbonated beverages being so short, it is crucial that they are saved appropriately to maximize their shelf life. The best means to keep these carbonated beverages is in the dark, cool, and also dry locations. A few of the very best storage space areas consist of fridges as well as ice chests.

There are a number of advantages that can be had when firms sterilize their items making use of the Tunnel pasteurization process. The items are pasteurized without enhancing the level of acidity in the drink. The item is not polluted with residuals of the manufacturing procedure or microbes. The beverage can be kept quickly and at heats. Sterilizing the beverages additionally shields them from oxidation, bring about the devastation of the taste and the original color of the product. Pasteurization of these carbonated beverages additionally gets rid of the need for expensive process to reverse the aging process of the carbonated beverages.

When using a tunnel pasteurization process to generate carbonated beverages, there are a few steps that need to be complied with. When preparing the carbonated beverage to be pasteurized, one will need a sterile buffered buffer, stainless-steel container and a laughing gas catalyst. Depending on the sort of carbonated beverage being generated, one might need extra ingredients such as a salt hydroxide (caustic soda) option. Once the carbonated beverage has actually been prepared, it must be flash frozen to remove any type of ambient temperature modifications.

A Guide To Tunnel Pasteurization For Beverage Items, Particularly Alcoholic Beverages

A leading sector standard for beverage items, especially alcohols, is via the use of "Tunnel Pasteurization." This pasteurizing approach has actually gained popularity with an increase in demand for the item as well as its equipment. Tunnel pasteurization equipment is used for several types of liquors consisting of white wines, spirits, beer and also some cocktails such as lemonade. It likewise is generally used in the processing of other food, particularly foods that have been fermented with yeast or contain considerable amounts of sugar.

The main ingredient of this sort of pasteurization system is a mixture of natural components such as yeast, vinegar, water as well as malt extracts. The white wine is typically overlooked the open stream of the tube at the price of one inch per second as well as the temperature level stays consistent throughout. In a passage pasteurization procedure, the bottle is typically covered for regarding fifteen mins before being opened. The temperature in the bottle will certainly be regulated by a temperature level controller that is usually an electronic gadget that shows an electronic display screen indicating the temperature.

One crucial aspect of this type of pasteurization procedure is that the high-quality containers or cans are utilized and then they are returned to the holding area. In the canister or bottle, the red wine or spirits are mixed with lactic acid to start the aging procedure. Usually the bottles are then returned to the handling line for a final proofing of the drink before it is packaged and shipped. The cans used in this process needs to undergo an extra intense proofing procedure, which lasts longer and can use up to four days depending on the size of the cans. The processing of the drink is total prior to the cans are returned to the holding location.

The main benefit to making use of the Tunnel pasteurization system is the defense of the drink from oxidation. Premium glass of wines and spirits contain a high focus of ferrous iron, which causes the development of ferric oxide which in turn causes the white wine or spirits to end up being over cast. This procedure of oxidation additionally creates refined changes in the flavor and also fragrance of the beverage. As a result, these products need defense from any type of modifications in temperature level and also oxidation.

To accelerate the aging process, suppliers of great alcohols generally make use of a tunnel pasteurization procedure in addition to a strong dose of salt hypochlorite. In addition to securing the beverages from oxidation as well as adjustments in taste and also aroma, this approach likewise postpones the beginning of light yellowing, range and cracking. A sterilized filtration unit is utilized to achieve this outcome as well as a huge scale air pump. Once the pasteurized beverage passes through the clean and sterile purification system, it is held for a time period. The air pump is utilized to check the product's progress via different phases of light yellowing, range and also cracking.

Tunnel pasteurization procedures are used for a range of products such as shampoos, soaps, red wines, beer and spirits. It is essential that all of these items go through similar kinds of pasteurization to make certain that they maintain the exact same look while still supplying the top quality they are developed with. As a result, one end of the procedure constantly makes use of a similar vessel or container in order to accomplish the very best results. At one end of the procedure, a reduced temperature level pasteurization device will certainly be heated up prior to the begin of the process while at the other end the item is cooled off to area temperature. Depending upon the kind of product as well as the process being conducted, some items are pasteurized at one end while others are pasteurized at both ends. In https://www.dairyfoods.com/articles/94778-maryland-virginia-milk-producers-cooperative-association-is-delivering-on-promises to utilizing the same vessels in the two different processes, both end times should be very comparable.

2 types of pasteurization procedures are made use of in this sort of organization. There is the flash pasteurization process in which the items are heated to between 2 hundred degrees Fahrenheit as well as 8 hundred degrees Fahrenheit. The flash pasteurization temperature level depends on what is required of the item being cooled. Blink pasteurization is the fastest of the two approaches, yet might not be the most reliable for carbonated beverages and also various other items that have a reduced boiling point.

Warmth therapy is an additional technique used to pasteurize liquids. Heat treatment happens when the high temperature of the vacuum cleaner resource is allowed to slowly vaporize the liquid prior to its contact with any other liquids. Most of the times, the heated liquids are permitted to sit as well as cool down with no contact with any other items. This pasteurization process is really reliable for carbonated beverages as well as other products with a high boiling point.

The Tunnel Pasteurization Process And Also Its Benefits

The Tunnel pasteurization procedure is one means to make sure high quality wines are created for consumers. When using this procedure, the pasteurization of a glass of wine or grape juice takes place in a tank that contains both the red wine and also the product being maintained at the same time. There are three temperature level levels that can be used in this kind of pasteurization strategy. The very first two methods are the sublimation and the carbon dioxide settings.

Tunnel pasteurization process used in the production of beer is frequently referred to as the coolship fermentation. This procedure uses regarding two quarts of beer for every gallon of product generated. Throughout this treatment, the coolship vessel including the beer is placed in an amazing dark place such as a basement or garage. The temperature level is generally in between forty-five as well as fifty-five levels Celsius.

Most of the items created in the United States undertake the Tunnel pasteurization process. In order to create the high-quality wines, sterilizing the product has to happen at the proper temperature level and also for an enough size of time. The item that should undergo this procedure is referred to as quenched beverage items. The products that are used to make sodas, teas, and flavored drinks are called quenched beverages. Both main sorts of items that need to experience this procedure are red wine and also sparkling wines.

“HOW TO DECREASE OXIDATION IN THE BREWING PROCESS”

— PRO ENGINEERING (@Daveone1) October 14, 2021

Article Release for Brewmasters & Beverage Makers by David Kapral, Founder/CEO: Brewing Consulting Services, LLC

Article Link:https://t.co/iYyjufi5iG

PRO Engineering / Manufacturing, Inc

414-362-1500 pic.twitter.com/JdhwqBTSTo

There are three ways to sterilize drinks. These consist of the hot water/cool water, the cold water/cool water set pasteurization procedure, and the spray bottle pasteurization procedure. There are differences between these techniques. It is very important to keep in mind that the longer the bottles are entrusted to go through the Tunnel pasteurization procedure, the much better the quality of the product will certainly be.

One means to utilize this approach is for the packaged bacteria to get in the bottles. When the bottles are secured, they do not position any dangers of the bacteria growing as well as multiplying as soon as inside. This is because the microorganisms grow at a quick price when they are available in contact with some sort of food resource like the bacteria that grow inside the packaging line. When the microbes are eliminated or dried out, the bottles are then placed on a rack for later use. Throughout https://www.bakeryandsnacks.com/Article/2019/10/07/Blue-Diamond-opens-Salida-plant-expansion-with-modern-pasteurization-tech manufacturing process, the company can likewise sterilize the beer before it enters contact with the product packaging line.

The shelf life of the packaged items that are sterilized making use of the Tunnel pasteurization procedure can likewise last for as long as 24 hours after the items are secured in the product packaging lines. With the shelf life of the packaged beverages as well as various other carbonated beverages being so short, it is necessary that they are saved effectively to maximize their shelf life. The best means to store these carbonated beverages remains in the dark, trendy, as well as completely dry locations. Several of the best storage locations consist of refrigerators and also ice chests.

There are a variety of benefits that can be had when companies pasteurize their items using the Tunnel pasteurization procedure. The products are pasteurized without enhancing the level of level of acidity in the drink. The item is not polluted with residuals of the manufacturing process or microbes. The beverage can be stored easily as well as at heats. Sterilizing the drinks also protects them from oxidation, bring about the destruction of the taste and also the original shade of the product. Pasteurization of these carbonated beverages additionally removes the requirement for pricey process to turn around the aging process of the carbonated beverages.

When making use of a passage pasteurization process to create carbonated beverages, there are a few actions that need to be followed. When preparing the carbonated beverage to be pasteurized, one will need a clean and sterile buffered buffer, stainless steel container and a nitrous oxide stimulant. Depending on the sort of carbonated beverage being produced, one might need additional components such as a salt hydroxide (caustic soda) solution. When the carbonated beverage has actually been prepared, it ought to be flash frozen to eliminate any type of ambient temperature modifications.

An Overview To Tunnel Pasteurization For Beverage Items, Particularly Alcohols

A leading industry standard for drink products, especially alcohols, is through making use of "Tunnel Pasteurization." This pasteurizing technique has gotten popularity with a rise in demand for the product and its equipment. Tunnel pasteurization devices is used for many kinds of liquors consisting of red wines, spirits, beer as well as even some alcoholic drinks such as lemonade. It also is commonly used in the handling of other food products, especially foods that have actually been fermented with yeast or have considerable quantities of sugar.

The main ingredient of this sort of pasteurization system is a mixture of natural components such as yeast, vinegar, water as well as malt extracts. The a glass of wine is usually overlooked the open stream of the tube at the rate of one inch per 2nd and also the temperature level remains consistent throughout. In a passage pasteurization procedure, the bottle is usually covered for concerning fifteen minutes prior to being opened. The temperature in the bottle will be regulated by a temperature level controller that is usually a digital tool that presents a digital screen indicating the temperature level.

One essential facet of this sort of pasteurization process is that the top notch containers or cans are made use of and after that they are returned to the holding location. In the container or container, the a glass of wine or spirits are combined with lactic acid to start the aging process. Commonly the bottles are then returned to the processing line for a last proofing of the drink before it is packaged as well as delivered. The canisters made use of in this procedure has to undergo an extra extreme proofing procedure, which lasts longer and also can occupy to 4 days depending on the dimension of the canisters. The handling of the beverage is total before the cans are returned to the holding area.

The main benefit to making use of the Tunnel pasteurization system is the defense of the drink from oxidation. High-quality glass of wines as well as spirits consist of a high concentration of ferrous iron, which causes the growth of ferric oxide which subsequently causes the red wine or spirits to come to be cloudy. This process of oxidation additionally triggers refined changes in the flavor and also scent of the drink. As a result, these items call for security from any modifications in temperature level as well as likewise oxidation.

To speed up the aging process, manufacturers of great liquors generally make use of a passage pasteurization procedure in addition to a strong dose of sodium hypochlorite. Along with protecting the beverages from oxidation and changes in flavor and also fragrance, this method additionally postpones the start of light yellowing, scale as well as fracturing. A sterilized filtration system is made use of to achieve this result along with a large range vacuum pump. Once the pasteurized drink passes through the clean and sterile filtering unit, it is held for a period of time. The air pump is used to keep track of the item's progress with various stages of light yellowing, scale and also cracking.

Tunnel pasteurization procedures are used for a selection of items such as shampoos, soaps, glass of wines, beer as well as spirits. It is essential that every one of these products go through comparable sorts of pasteurization to make sure that they maintain the exact same look while still giving the high quality they are created with. For that reason, one end of the process always uses a similar vessel or container in order to accomplish the best outcomes. At https://www.foodsafetynews.com/2011/08/pasteurized-milk-linked-to-yersina-outbreak/ of the procedure, a reduced temperature pasteurization device will certainly be heated before the start of the process while at the other end the item is cooled down to room temperature. Depending upon the type of product as well as the procedure being carried out, some items are pasteurized at one end while others are sterilized at both ends. Along with making use of the same vessels in the two various processes, both end times should be extremely similar.

2 types of pasteurization processes are utilized in this kind of organization. There is the flash pasteurization process in which the products are heated up to in between two hundred degrees Fahrenheit and 8 hundred levels Fahrenheit. https://cityroom.blogs.nytimes.com/2010/06/15/removing-a-mysterious-sell-by-date-from-milk-cartons/ depends upon what is required of the product being cooled. Flash pasteurization is the fastest of the two methods, however might not be the most reliable for carbonated beverages and other products that have a lower boiling point.

Warmth treatment is another technique used to pasteurize fluids. Heat therapy happens when the heat of the vacuum source is allowed to gradually vaporize the fluid before its contact with any other liquids. Most of the times, the warmed fluids are allowed to rest as well as cool with no contact with any other items. This pasteurization process is extremely efficient for carbonated beverages and also various other items with a high boiling point.

What Are Tunnel Pasteurization Equipment Used For?

The procedure of using Three-way Temperature Spray Batch (TTSB) pasteurizer for encapsulated beverage items like carbonated, dextrose, flavorful as well as various other pasteurized drink products coincides as any other sterilizing process. Co2, lp read this as vapor are the cornerstones for the TDS or Tri-carbon dioxide. Carbon dioxide, propane as well as vapor are contained in the bottles or cans of the drink products. Packaged drinks can be easily processed by using a top notch pasteurization tools for boosted conservation and also life span; this is referred to as pasteurization.

The term "Pasteurization" suggests raising the temperature of a things at a really high level, which is absolutely carried out in a container that has some type of warm generating system. In the context of this specific conversation, it is a good idea to point out that the containers discussed below remain in truth heated up using a conveyor belt. It takes place with conveying the warmed drink products from one container to another according to the conveyor's constant rotation. It certainly happens by continuously rotating a belt that is composed of multiple parallel plates on which the liquid is transferred to.

“TUNNEL AND BATCH PASTEURIZATION VERSUS ADDING ARTIFICIAL PRESERVATIVES TO FOOD AND BEVERAGES”

— PRO ENGINEERING (@Daveone1) October 7, 2021

Article Release for Brewmasters & Beverage Makers by Edward A. Michalski

Click for full article: https://t.co/vwPs0n4WKK

PRO Engineering / Manufacturing Inc.

414-362-1500 pic.twitter.com/C7huE0Vy4w

In basic terms, it is a popular reality that the sterilizing process has actually been used for many years to preserve different kinds of foods and also drinks. Specifically meat products such as beef, pork and also lamb need this type of treatment for an extended period of time. Foodstuff that have not been sterilized can additionally be securely made use of by using this type of therapy. This is because they are risk-free to consume because there are no traces of germs or fungi existing in them. The exact same treatment nonetheless can not be applied on breads or baked goods unless those products have been thoroughly sterilized initially.

The procedure is usually used for numerous procedures in which the process is essential, such as in preserving beer as well as various other ales. Nevertheless, one of the most popular use of this treatment remains in preserving white wine. The wine pasteurization procedure is likewise referred to as the "Wine Tunnel Pasteurization". There is in fact a bit of controversy relating to the real period of time that must be considered the items to be taken into consideration as risk-free to take in.

According to the majority of the red wine enthusiasts, this duration is too short. On the other hand, others think that it needs to be extended enough to make sure that the microbes are eliminated completely. Regardless of these disagreements, the point is that, there are numerous pasteurizers that can be selected based on their home heating capacity and depending on the type of beverage that is to be protected. The commonest sorts of a glass of wine pasteurizers are those that have a tool warming up power as well as are normally made use of for gewurztraminers and light brews. This kind of pasteurizer is also the most prominent.

On the other hand, there are additionally Tunnel established pasteurizers which are much larger than those that are readily available for microbrews and also high-gravity beers. These have a cooling capacity of almost 10 barrels. Some well known brand names of beers that take advantage of this process consist of Bell's Pils, Richer's Barley White wine, draft King, Hoppin' John, Lost Bridge, Design Beer, Sam Adams, Stone cool brew, Widmer's Bitter American, as well as Widmer's Dry Ales. The bottles in which such beers are shipped are particularly marked to bring the tags of the breweries in terms of the names of the beers as well as the names of the brand names. Aside from the bottles, it is also feasible to heat and cool the bottles making use of particularly designed chillers.

The Tunnel pasteurizer that is taken advantage of in the stated items are usually produced as 2 unique items. Among them is referred to as the primary boiler and the other is called the set boiler. In the primary boiler, the sterilized products are warmed to a temperature of around 150 degree Fahrenheit. When it pertains to the set boiler, the products are made right into froth by placing in a cold water cycle. It is in addition crucial to note that both sorts of central heating boilers are able to provide for pasteurization at fairly low temperatures.

Tunnel pasteurizers that are used in the process of making beer are known as one-place systems. These kinds of pasteurizers are manufactured making use of the concept of 2 various chambers. One chamber of the system is in direct contact with the product that is being sterilized while the various other one is in a completely enclosed environment. What takes place here is that the warm heavy steam from the boiler is made use of to heat the products that are in the one area chamber as well as the great water that come from the boiler is made use of to rinse the items that remain in the 2nd area. With the kind of pasteurizers that are being utilized, you will certainly understand that the amount of sterilized items is decreased to very much less amounts.

What Is The Tunnel Pasteurization Process?

In order for a popular and also skilled business to utilize the Tunnel pasteurization procedure for the manufacturing of their beer, one would certainly expect the top quality to be respectable. This is why many of these widely known companies have been using this technique in their processes. Nevertheless, when it concerns beer, or any other beverage for that issue, this method of pasteurization has its disadvantages. Although there are a number of various factors as to why this approach is not as effective as others, the most common factor is because not enough flash pasteurization containers are used to finish the entire process.

When making use of the Tunnel pasteurization procedure, inadequate containers are produced throughout the production procedure. Because of https://interestingengineering.com/louis-pasteur-and-the-birth-of-the-food-safety-pasteurization-process , not all of the beer generated is of the best high quality. The top notch beverage produced by these widely known companies just has a percent-quality of alcohol in it; the rest being water, sugar, as well as anemic movie agents. As a result of the reality that these bottles and containers only have twenty percent of the efficient dose of taste as well as scent, they do not offer very well.

Due to the smaller amount of bottles that are generated by this approach, much less can be sold contrasted to various other approaches. Another downside to this is since the pasteurizing process uses a chilly temperature rather than warm. simply click the up coming internet site implies that the pasteurizers need to go for a higher temperature level to obtain the bottles completely triggered. With a greater starting temperature level, even more can be activated to enter into the containers or containers and also this causes a reduced variety of bottles that are really marketed.

Tunnel pasteurization processes additionally have a tendency to not work effectively with liquors. The factor for this is since the alcohol in the beverage often tends to transform to acetic acid prior to being sent through the conveyor. Due to the fact that this Acetic acid is harmful to the preference of the drink, many companies do not use this procedure with their liquors. As a result, people end up having more powerful tasting beverages like beer since there is insufficient Acetone in the beverage to mask the preference.

Nonetheless, if you want your beer or soda to preserve its flavor, you will certainly intend to make the effort to locate a high quality sterilized product to utilize. There are firms that will send you your own containers of this product at no cost. If you are one of those people that take pleasure in having your very own brand names of bottled beverages, then obtaining one of these boxes at no charge is a fantastic method to conserve cash on your favorite drink. Simply ensure that you are obtaining an authentic product like one manufactured by a widely known company, as these more affordable products are not going to offer you with the same flavor and preference as their much more costly equivalents.

When it pertains to the Tunnel pasteurization process itself, you have to comprehend just how it works. Among the very first steps that are taken by the firm manufacturing the item is that the high boiling temperature level is preserved throughout the entire assembly line. This makes certain that all of the items undergo this long and thorough assembly line. As long as the temperature level stays at the high boiling point, absolutely nothing in the bottle will change. The item will certainly remain at its original temperature level throughout the manufacturing process.

During the actual beer pasteurization process itself, the bottle is first offered room temperature. After that, the bottles are positioned in the container. Within this container, there will be a light released by a device called a flash lamp. This light flashes about 7 times per 2nd, shining onto the beer inside the bottle at the same high temperature that the rest of the containers are at. This very high temperature will eliminate any kind of microorganisms or germs that are trying to stay in the bottle.

After everything has actually been killed off, the beer manufacturing procedure is complete. The item can be securely saved for up to two months each time. Although it will remain sterilized, it is very important that you constantly sterilize the bottles when they are removed from the developing system. This will ensure that your following batches of drinks are likewise sterilized.

Exactly How The Traditional Method Of Tunnel Pasteurization Utilized By Thermal Distillers?

The standard method of Tunnel pasteurization utilized by thermal distillers as well as similar thermal oxidizing systems entails making use of several warm exchangers for the oxidation of chemical reactions. In such a system, 3 or more heat exchanger units are required for the whole response, which calls for a large amount of space. In recent researches, making use of nano innovation, scientists have developed a novel chemical shipment system that can make use of nano tubes to atomize molecules in solution, developing polar particles with high electrical charges. These polar molecular bits are then delivered to a separate chamber where they can go through electrodialysis reactions to create charged polymer chains.

This cutting-edge thermal oxidizing system, which entails using nano tubes, is based upon the Tunnel pasteurization process. Standard thermal dilution of chemical materials generally involves the blending of dilute chemicals in high-pressure containers. Heat produced throughout the blending of these chemicals is transferred to the liquid medium, which leads to the dissipation of some of the chemicals and the transformation of others into much less thick substances. In you could look here of pure liquids, the procedure likewise results in the development of heavy steam.

Thermal purification and also carbonation are commonly utilized by bottling companies to extend the shelf life of their popular beverages. In simply click the up coming internet page , nevertheless, there has been enhancing demand for foods and also beverages that are not carbonated or seasoned, in addition to other beverages that have greater concentrations of unstable active ingredients than various other standard liquids. To meet this demand, producers of carbonated beverages and many mineral water alternatives have actually established the Tunnel pasteurization procedure. With this process, they can minimize the dissipation of tasty and carbonated beverages, while preserving their life span. The procedure likewise reduces the demand for additives, such as sugar, that considerably enhance the life span of carbonated beverages and other sorts of fluids with high focus of dissolved solids.

The Tunnel pasteurization process is specifically useful for canned and also bottled beer, because it enables the carbon dioxide in the product to exchange carbonic acid, which is needed to break down the proteins in the foam. The conversion of CO2 into acid causes the fresher taste of several tinned and also bottled beers, while getting rid of the requirement for expensive emulsifiers. Lots of beers are pasteurized at temperatures of around 150 levels Fahrenheit, although numerous brands are sterilized at lower temperature levels. The pasteurizing process, in addition to pasteurizing fluids that consist of fruit juices and various other high-acidifying products, allows beer makers to sterilize their items without giving up taste.

“IMPROVED MARKETING FOR CRAFT BREWERS”

— PRO ENGINEERING (@Daveone1) August 9, 2021

Article Release for Brewmasters & Beverage Makers by Paul Spellman, President of Craft Brewers’ Consultants

Click Here for full article: https://t.co/WZ2JYKFKC8

PRO Engineering / Manufacturing Inc.

414-362-1500 pic.twitter.com/8jBP5QLgWE

This pasteurizing method can be applied to many kinds of bottled beverage products, including but not limited to: carbonated, deionized, hard, normal, springtime, reduced, non-carbonated, and also alcoholic beverages. The application procedure can be done through 2 various sorts of equipment. One type of equipment heats the fluid utilizing a heavy steam stress vessel. The various other type of tools heats the liquid making use of an oxygen generator, producing a high-pressure stream of liquid. Each of these methods requires separate steps to complete, however both kinds can offer superb top quality as well as flavor in the ended up items. Sometimes, the process can be incorporated to develop a much more economical manufacturing technique for a producer.

The Tunnel pasteurization procedure generates an extremely tasty item. It is frequently utilized for mass-market soft drinks and for numerous packaged drinks in grocery stores. Several firms refine these products as an alternative to flash pasteurizing or traditional pasteurizing. Sterilized soft drinks undergo a flash procedure, where flash icy items go through a very extreme heating procedure to sterilize as well as shield them from contamination. Pasteurized hard as well as routine drinks go through a traditional pasteurizing process, where flash frozen products are subject to a much more extreme home heating process to attain pasteurization. Furthermore, this sterilizing process likewise safeguards the bottles from possible contamination with microbes and also bacteria.

The primary step of the Tunnel pasteurization procedure is to bring the bottles to room temperature level, and then start the process by filling a sterilized buffer storage tank with tap water. The clean and sterile buffer container must be at space temperature so that the pasteurized item will preserve its preference and also structure. When the clean and sterile buffer tank has actually been loaded with water, it is necessary to eliminate any air pockets within the bottle that would certainly prevent the sterilized liquid from reaching its complete temperature. This process is called priming. After priming, the bottles are positioned in the warmth chamber to begin the flash pasteurizing process.

During the flash pasteurization process, the bottles' lids are put on top of a heat resource, such as a heating element on a warm water bottle. A dial with a variable control is after that put right into the bottle's control box. This dial enables the temperature of the water consisted of within the bottles to differ. The bacteria existing in the faucet water will normally heat up as a result of being exposed to warm water, allowing the preferred microbial matter as well as appearance of the item to be gotten to.

What Are Tunnel Pasteurization Systems Utilized For?

The procedure of using Triple Temperature level Spray Set (TTSB) pasteurizer for encapsulated drink products like carbonated, dextrose, flavored and various other pasteurized beverage items is the same as any other pasteurizing process. Carbon dioxide, propane and vapor are the cornerstones for the TDS or Tri-carbon dioxide. Co2, gas and also vapor are contained in the bottles or canisters of the drink products. Packaged drinks can be easily refined by using a high-grade pasteurization devices for improved preservation and life span; this is called pasteurization.

The term "Pasteurization" means raising the temperature of an object at a really high level, which is certainly performed in a container that has some sort of warm producing system. In the context of this particular discussion, it is recommended to point out that the containers stated here are in reality heated through a conveyor belt. It takes place via communicating the heated beverage products from one container to another according to the conveyor's continual turning. It definitely occurs by constantly rotating a belt that is composed of numerous identical plates on which the liquid is transferred to.

In simple terms, it is a well-known truth that the pasteurizing procedure has actually been employed for years to maintain various sorts of foods and beverages. Particularly meat items such as beef, pork and also lamb require this sort of therapy for an extended period of time. Food products that have actually not been pasteurized can likewise be securely made use of by applying this kind of therapy. This is because they are risk-free to consume since there are no traces of bacteria or fungi present in them. The same treatment nonetheless can not be applied on breads or baked products unless those items have actually been extensively sterilized first.

The process is typically made use of for numerous processes in which the process is needed, such as in maintaining beer as well as various other ales. Nonetheless, one of the most famous use this procedure is in maintaining white wine. The white wine pasteurization procedure is also known as the "Red Wine Tunnel Pasteurization". There is really a little controversy concerning the real duration of time that should be taken for the items to be thought about as secure to consume.

According to the majority of the white wine fanatics, this duration is also brief. On the other hand, others think that it ought to be extended enough to make sure that the bacteria are eliminated completely. No matter these debates, the point is that, there are numerous pasteurizers that can be chosen based upon their heating capability and depending on the type of drink that is to be protected. The commonest sorts of wine pasteurizers are those that have a tool heating power and also are normally used for gewurztraminers and also light beers. This sort of pasteurizer is likewise one of the most prominent.

On the other hand, there are additionally Tunnel set pasteurizers which are much larger than those that are readily available for microbrews and high-gravity beers. These have a cooling ability of virtually 10 barrels. Some well known brand names of beers that take advantage of this process consist of Bell's Pils, Fuller's Barley Red wine, draft King, Hoppin' John, Lost Bridge, Model Beer, Sam Adams, Stone chilly brew, Widmer's Bitter American, as well as Widmer's Dry Ales. The bottles in which such beers are shipped are particularly marked to bring the tags of the breweries in regards to the names of the beers and the names of the brand names. Besides the bottles, it is likewise possible to warmth as well as cool down the bottles making use of specially designed refrigerators.

The Tunnel pasteurizer that is made use of in the stated products are generally fabricated as two distinct items. One of them is known as the main boiler and also the other is called the batch boiler. In the key central heating boiler, the sterilized items are heated to a temperature of around 150 level Fahrenheit. When it concerns the batch boiler, the products are made into froth by placing in a cold water cycle. https://www.perishablenews.com/dairy/kalona-supernatural-showcases-its-new-100-certified-grass-fed-cows-milk-kefir-at-2020-natural-products-expo-west/ is additionally vital to keep in mind that both sorts of boilers have the ability to provide for pasteurization at fairly reduced temperatures.

Tunnel pasteurizers that are used in the process of making beer are known as one-place systems. These kinds of pasteurizers are produced making use of the concept of two various chambers. https://www.foodsafetynews.com/2019/07/milk-pasteurized-on-the-farm-suspected-of-causing-illnesses/ of the system is in direct contact with the product that is being pasteurized while the other one is in an entirely enclosed atmosphere. What happens below is that the warm vapor from the boiler is made use of to heat the products that remain in the one area chamber and also the cool water that come from the central heating boiler is used to wash the products that remain in the second area. With the kind of pasteurizers that are being used, you will realize that the amount of sterilized items is decreased to really much less quantities.

What Is The Tunnel Pasteurization Refine?

In order for a well-known and knowledgeable firm to make use of the Tunnel pasteurization procedure for the production of their beer, one would anticipate the high quality to be pretty good. This is why most of these popular firms have actually been using this approach in their processes. Nonetheless, when it involves beer, or any other beverage for that issue, this technique of pasteurization has its drawbacks. Although there are a number of various reasons as to why this technique is not as effective as others, the most common factor is since not nearly enough flash pasteurization storage tanks are made use of to complete the entire process.

When using the Tunnel pasteurization process, inadequate bottles are produced throughout the manufacturing procedure. Because of this, not all of the beer created is of the best quality. The premium drink created by these widely known firms just has a percent-quality of liquor in it; the rest being water, sugar, as well as anemic movie agents. As a result of the truth that these bottles as well as canisters just have twenty percent of the effective dosage of taste and also aroma, they do not offer effectively.

As a result of the smaller sized amount of bottles that are created by this method, much less can be marketed contrasted to other techniques. Another disadvantage to this is since the sterilizing procedure utilizes a cool temperature level rather than hot. This indicates that the pasteurizers have to run at a greater temperature to get the bottles totally triggered. With a greater starting temperature, even more can be turned on to enter into the canisters or bottles and this causes a reduced variety of containers that are really offered.

VIDEO: “SIMULATION of TUNNEL PASTEURIZATION USING a TRIPLE TEMPERATURE SPRAY BATCH PASTEURIZER”

— PRO ENGINEERING (@Daveone1) August 3, 2021

Video Summary of Article Release for Beverage Makers

Video Link: https://t.co/QSnnN8UJhM

Article Link: https://t.co/oDnRmyOlOa

PRO Engineering / Manufacturing Inc.

414-362-1500 pic.twitter.com/kK7IlYsCp4

Tunnel pasteurization procedures likewise tend to not function very well with liquors. The factor for this is since the alcohol in the beverage tends to convert to acetic acid prior to being sent out via the conveyor. Because this Acetic acid is harmful to the taste of the beverage, many business do not utilize this procedure with their liquors. Therefore, individuals wind up having stronger sampling drinks like beer since there is not nearly enough Acetone in the drink to mask the taste.

However, if you desire your beer or soda to maintain its flavor, you will certainly intend to put in the time to find a high quality pasteurized item to utilize. There are companies that will certainly send you your very own containers of this item at no charge. If you are one of those individuals that appreciate having your very own brand names of bottled drinks, after that obtaining among these boxes at no cost is a great means to save money on your favorite drink. Simply ensure that you are obtaining an authentic product like one made by a popular firm, as these less costly products are not going to give you with the same taste and taste as their a lot more expensive counterparts.

When it involves the Tunnel pasteurization procedure itself, you have to understand exactly how it works. Among the initial steps that are taken by the firm making the item is that the high steaming temperature level is maintained throughout the entire assembly line. This makes sure that all of the items go through this long and also comprehensive assembly line. As long as the temperature level stays at the high boiling point, nothing in the bottle will alter. The item will certainly remain at its original temperature throughout the manufacturing procedure.

During https://www.livescience.com/13057-breast-milk-ice-cream-seized.html , the bottle is first given room temperature level. After that, the bottles are placed in the container. Within this container, there will be a light discharged by a device called a flash lamp. This light flashes about seven times per 2nd, shining onto the beer inside the bottle at the exact same high temperature that the remainder of the bottles are at. This exceptionally high temperature will kill any microorganisms or microorganisms that are trying to stay in the bottle.

After every little thing has actually been killed off, the beer manufacturing process is total. The item can be safely kept for up to two months at once. Although it will certainly remain sterilized, it is essential that you constantly sterilize the bottles when they are removed from the brewing system. This will certainly guarantee that your next batches of drinks are also sterilized.

Things To Learn About A Tunnel & Batch Pasteurizer Equipment

Passage & Set Pasteurizers are an unique class of pasteurizers particularly developed to manage the growth of microbes in either liquid or semi-solid tool. Pasteurizers are typically thought about among the very best types of sterilizers for usage in personal as well as industrial setups. They provide regulated and also monitored temperatures as well as high degrees of chemical concentration for applications where temperature level and chemical concentration is an issue. A selection of other factors, such as oxidation, direct exposure, response as well as range, can impact the buildings as well as performance of a pasteurizer.

Tunnel & Batch Pasteurizers are generally made use of in conjunction with warm water heating systems for their ability to reduce unstable organic substances (VOCs) generated throughout the heating process. These VOCs become airborne after the VOCs have completed their burning in the boilers. As these substances work out to the bottom of the storage tank, they are launched right into the environment. Learn Alot more of VOCs are associated with wellness concerns such as irritation, anxiety, headaches, asthma and cancer.

The burning products of the boilers in personal treatment, automobile and also healthcare sectors produce a large quantity of VOCs that are believed to be responsible for hundreds of fatalities and also illnesses every year. By utilizing a heavy steam shower along with a pasteurizer, you can help reduce the manufacturing of these damaging chemical residues. There are 2 kinds of Tunnel & Set Pasteurizers available: wet as well as completely dry. Each sort of pasteurizer has a various means of having chemicals and gases, causing a special mix of temperature as well as chemical focus.

Tunnel & Set Pasteurizers are available in various styles and setups to satisfy the demands of any kind of sector. They are suitable for both commercial as well as household applications because they can be tailored to fit the requirements of the customers. relevant internet site and also completely dry types appropriate for restrooms and similar locations, as their names suggest, where liquids and also gases are being used. If vapor is made use of, the damp selection of pasteurizer need to be used; if water, after that the completely dry type must be utilized. Both sorts of Tunnel & Set Pasteurizers are ideal for cleaning up applications due to the fact that they have the necessary innovation for cleansing.

" title="PRO Engineering / Manufacturing Inc. specializing in tunnel pasterizers and batch pasteurizers for brewmasters & beverage makers">

A typical Tunnel & Set Pasteurizer equipment have the following fundamental elements: 2 tanks, a warmth source such as a heavy steam central heating boiler or direct existing (DC) electrical power, an electrodialysis system and a tunnel pasteurizer unit. The container is developed to hold a high temperature water remedy, while the storage tanks hold a cleaning tool, typically anhydrous ammonia. The electrodialysis system extracts electrodialysis water from the tool in the storage tank as well as transfers it to the warmth source, which warms up the water and also expands it right into a gas. The warmed gas is after that injected right into the tank in established patterns to generate heavy steam.

Tunnel & Set Pasteurizers can be purchased through a powdered tool which contains cooking soda, which when blended with an electric existing, produces heat. Nonetheless, powdered tools are not suggested because of wellness problems; therefore, it is best to acquire anhydrous pasteurizers that are offered without the powder. Other pasteurizers are more suitable to utilize due to the fact that they do not produce warmth, however rather, release heavy steam into the system when heated up. A few instances of such pasteurizers are the warm roll pasteurizer, the hot smoke pasteurizer, the warm pasteurizer and the instantaneous pasteurizer. Immediate pasteurizers are excellent for pastry shop operations, food handling plants as well as even for clinical research laboratories.

There are a number of advantages of using A Tunnel & Batch Pasteurizers over a conventional oven-based pasteurizers. First, they do not produce smoke or steam, which is a substantial wellness worry in food handling plants. Second, they are much faster to warm up and also less most likely to burn excess liquid throughout handling. Last but not least, they are safe for all kinds of customers, whether homemade or restaurant. It is also vital to note that considering that they do not utilize vapor, they are more secure to use than traditional stoves. This suggests that a Cavern & atch Batch Pasteurizer Device coal discharged or anhydrous can be used on foods that are cooked on standard boilers or ovens.